Product features:

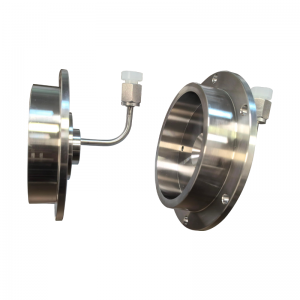

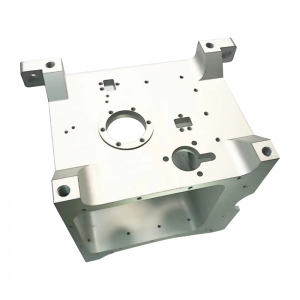

High-precision processing: Through five-axis linkage technology, continuous processing of multiple angles and surfaces is achieved, reducing the errors caused by multiple clamping, ensuring dimensional accuracy and surface quality.

Support for complex structures: It can process parts with complex geometric shapes, such as curved surfaces, inclined holes, deep cavities, etc., to meet the special needs of high-end equipment for parts.

Multi-material compatibility: Supports the processing of various materials such as aluminum alloy, stainless steel, titanium alloy, copper, plastic, etc., to meet the performance requirements of different application scenarios.

Various surface treatments: Provide a variety of surface treatment methods such as anodizing, electroplating, sandblasting, polishing, etc. to improve the corrosion resistance and aesthetics of the product.

Customized service: It can be customized and developed according to the drawings or samples provided by the customer, supporting small batch trial production and large batch production, and flexibly meeting customer needs.

Application areas:

Aerospace: such as engine parts, structural brackets, etc.

Medical devices: such as surgical instruments, implants, etc.

Automobile manufacturing: such as engine parts, transmission system parts, etc.

Electronic equipment: such as radiators, connector housings, etc.

Automation equipment: such as robot joints, fixtures, etc.

We are committed to providing customers with high-quality and reliable five-axis CNC machined parts to help customers improve the overall performance and market competitiveness of their products.

评价

目前还没有评价